This site uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site you find most interesting and useful.

The world has been deeply disrupted by the health crisis, lockdowns and border closures. Companies continue to suffer the aftermath of the disruption in their supply chain management, as suppliers have seen their own supply chains directly impacted by the crisis. This is particularly the case in Asia, more specifically in China, a country that remain closed to foreigners, but which represents an irreplaceable source for certain materials and parts central to production. In this context, the use of companies already established in this country allows to find stability in supplier relationship in order to maintain production levels.

An unstable context and many uncertainties

The rebound in production and recovery of activity at a global level was the major topic of 2021. However, after months at a standstill, some sectors are struggling to restart, which represents a major problem for production activities and related clusters. We have already explained the causes of the increase in raw material prices, and our experts have published articles in the European media explaining the different strategies to be deployed to face it.

Double or triple sourcing strategies, as well as the search for alternative suppliers, tend to be favored when companies are looking for alternatives to supply chain disruption. They are more realistic and take less time to implement than product reengineering or redesign to cost, which can be an excellent medium to long term lever, but requires a significant investment over a longer time horizon that depends on the efficiency of the research and development function.

Nevertheless, the control of current suppliers, as well as the search for alternative suppliers, proves to be extremely complicated when we are talking about closed countries like China. The supplier relationship, the cornerstone of any production operation, can be precarious and must be nurtured constantly. Exchanges must be recurrent: not only to guarantee a better position in case of price negotiation or contract renegotiation, but also to ensure quality control and compliance with norms and the company’s CSR policy.

How to secure your supply chain sourcing in China during the COVID era

By using groups already established overseas, companies all around the world can renew their supplier relationships and secure their supplies. Disruptions in production, difficulty in finding containers or negotiating with carriers, are handled by experts on the ground and resolved very quickly. The price increase of raw materials, as well as costs of suppliers, carriers and deliverers, are all attacked directly, which guarantees a better result than negotiating remotely, via video conference, in a different time zone.

EPSA’s experts are able not only to defend the interests of our clients, but also to provide timely recommendations to cope with the COVID period. Having an expert on site improves the management of communication with suppliers, reporting and monitoring of results. It is a win-win strategy in which suppliers are reassured, as they keep their historical customers, and foreign companies secure their supply under the best possible conditions.

Controlling compliance with standards

When companies use foreign suppliers, they are obliged to ensure compliance with national production standards, labor codes and human rights. Sometimes, remote controls are not enough and companies are obliged to travel to ensure compliance and propose areas for improvement.

Obviously, this logic is completely broken today, as China doesn’t accept foreign travelers. As a result, the lack of audits and on-site visits by the customer will have a negative impact on the quality of the purchased product, a major problem that can bring the supply chain to a complete stop.

The same is true for human rights and labor laws: no one can know from afar if these are respected, if the unacceptable practices of making workers work non-stop or employing minors have not reappeared. The exploitation of children and minorities adds to the impossibility of guaranteeing the respect of the CSR policy established by the company, a subject of increasing importance for consumers. Companies are devoting increasingly larger budgets to CSR; the use of experts on the ground ensures that the investment made upstream is not lost and guarantees the sustainability of this initiative.

Proven experience in the field

At a time when China remains closed to foreign travelers and companies need to secure their supply in Asia, EPSA China, with our 35 specialized consultants, helps you maintain production levels, as well as guaranteeing the control of suppliers and accurate on sight reporting:

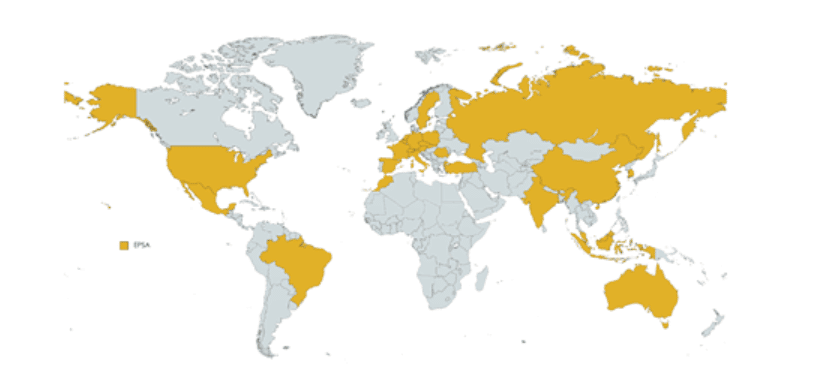

EPSA Around The World

If you have any questions, please feel free to contact us via our online form.